CONCRETE REINFORCEMENT SCANNING IN TEXAS

When is concrete scanning needed?

Many times, home or commercial renovation projects require the coring or trenching (cutting) of concrete for plumbing and utility lines relocation. Our concrete scanning services are executed with the proper technology and technical experience that can prevent costly damage within foundations or structural components. Concrete coring or cutting without scanning may lead to the partial or complete damage of foundation beams, electrical conduit, water plumbing, rebar, or structural post-tensioned cables.

When construction assessment or retrofitting is required to determine the load bearing capacity of old reinforced concrete structures and the original plans are not available, concrete scanning can provide details of the reinforcing steel configuration, rebar diameters, depth and orientation.

Moreover, when concrete coring is required, it is not recommended to drill through steel reinforcement as this may damage the structure’s load bearing capacity. At the same time, the American Concrete Institute does not accept the testing of concrete cores with included rebar as a basis to determine the compressive strength of a structure.

What is a concrete scan?

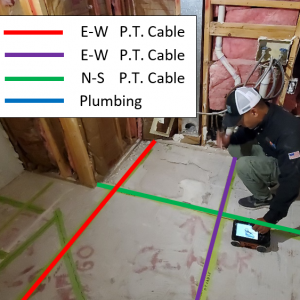

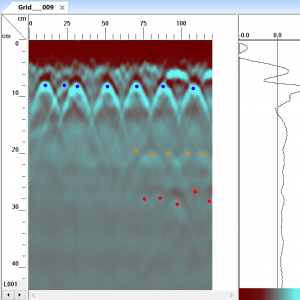

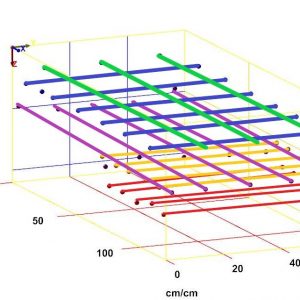

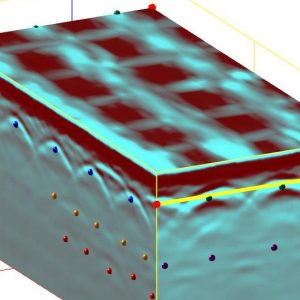

Also commonly called concrete X-Ray, a concrete scan is a testing method that reveals reflective objects inside concrete. Such objects can be rebar (metal), post-tensioned cables, electrical conduit, PVC pipes, plumbing utility lines, etc. These objects are found by means of the implementation of hand-held antennas inducing safe to the public electromagnetic waves into concrete. Based on the responses of internal targets, we can generate a Bidimensional or Tridimensional Image of reflective objects inside concrete.

How do we scan concrete?

We are equipped with industry leading technology and an experienced team of technicians with knowledge of both concrete construction and condition assessment of new or existing structures.

– We ask the customer for the reason of scanning

– We conduct a remote or on-site visual examination of the structure to scan

– Using our concrete scanning tools, we obtain all necessary information from the structure

– If needed, we can provide the customer with on-site markings of all utility lines or reinforcing steel found within the tested area. We can even mark safe drilling or coring locations

– If structural detail is needed, our work is complemented by delivering a comprehensive report containing rebar configuration, spacing, and diameter

What tools do we use?

GPR o Ground Penetrating Radar: Detailed Rebar Location

Ground Penetrating Radar GPR is the industry leading technology for concrete testing professionals. We are equipped with high resolution GPR scanners that will ensure the best possible detail of the internal reinforcing steel configuration, and location of utility lines. GPR is a non-radioactive and safe to use technology that is versatile to implement in many types of structures. Our GPR can generate 2D or 3D imaging.

Covermeter: Rebar Location and Diameter Testing

Covermeter is a high-end metal detector that is used to locate the electromagnetic signal of near surface rebar in concrete slabs, foundations, beams, girders, columns, etc. The implementation of this method can also provide the approximate rebar diameter to properly compliment the Ground Penetrating Radar scans.